Search This Supplers Products:tungsten carbide tools

CBN Cutting tools manufacturer

- group name

- PCD & CBN Inserts

- Min Order

- 1 piece

- Nearest port for product export

- SHENZHEN, CHANGSHA

- Delivery clauses under the trade mode

- FOB, CIF, EXW, Express Delivery

- Acceptable payment methods

- T/T, PayPal, Westem Union, Cash

- Export mode

- Export through agents & Have the independent export and import right

- update time

- Mon, 12 Mar 2018 15:36:26 GMT

Paramtents

material polycrystalline cubic boron nitride

Packging & Delivery

-

Min Order1 piece

Briefing

Detailed

Our PCBN blanks for cutting tools have two series of CB and BN. CB series is composed of CBN layer and tungsten carbide base. BN series is solid CBN. Customers can choose suitable PCBN material with different CBN contents, grain sizes and grades according to turned object material.

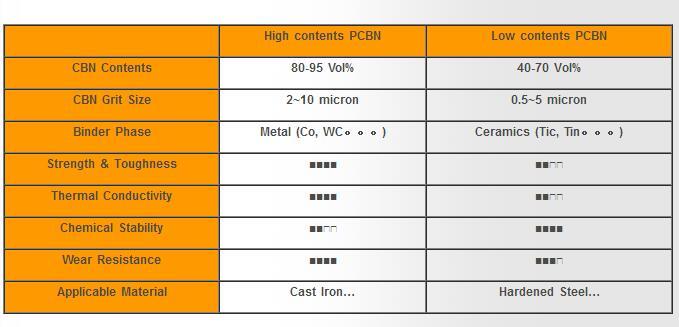

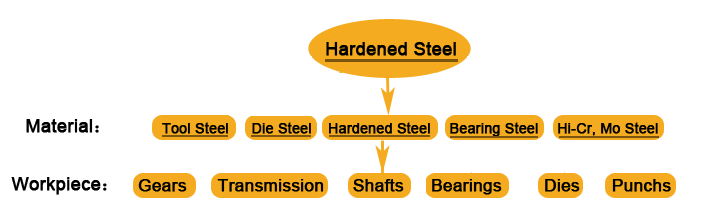

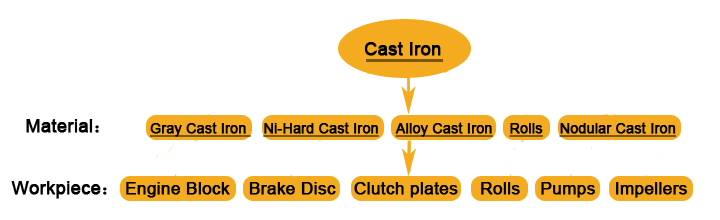

In general, high content PCBN is used in cast iron applications while low content PCBN is used in hardened steel applications.

Type | Solid PCBN | |

Grade | BN90 | BN85 |

CBN (vol.%) | 90 | 85 |

Grain size | 3 | 3 |

Main Binder | Al-Co | Titanium Nitride and Aluminum |

Hardness | 3500-3700 | 3300-3500 |

Characteristics | Excellent fracture resistance, better wear resistance, good chemical stability, multi edges, long life | Excellent fracture resistance, better wear resistance, good chemical stability, fine finish, long life |

Application | Hard cast iron, hardened steel, Pearlitic gray cast iron, hard facing alloy, powder metallurgy metals, fine turned nickel and cobalt base alloys etc. | Hard cast iron, hardened steel, Pearlitic gray cast iron, hard facing alloy, powder metallurgy metals etc. |

Type | Carbide back supported | ||||

Grade | CB90 | CB85 | CB70 | CB60 | CB50 |

CBN (Vol%)

| 90 | 85 | 70 | 60 | 50 |

Grain size (μm) | 3 | 3 | 3 | 3 | 2 |

Main Binder | Al-Co | Ceramic of Al system | Ceramic of Al,Ti system | TiC and TiN | TiN |

Hardness (Hv) | 3500~3700 | 3300~3500 | 2700~2900 | 2600~2800 | 2500~2700 |

Characteristics | High wear resistance, thermal stabiligy, better impact resistance, high quality surface finish | High wear resistance, better impact resistance, high cutting efficiency and long life | High wear resistance, good thermal stability | High wear resistance, strong chemical stability, good transversal rupture strength resistance. | High wear resistance, high thermal conductivity, chemical stability, fine finish and long life |

Application | Pearlitic gray cast iron, tool steel, die steel, hard facing alloy, powder metallurgy metals, fine turned nickel and cobalt base alloys etc. | Hard cast iron, hardened steel, Pearlitic gray cast iron, hard facing alloy, powder metallurgy metals etc. | Machine high speed steel continuously and interruptedly etc. | Machine hardened steel, tool steel and die steel continuously and interuptedly etc. | Hardened Steel, die steel |